FLASH System

Your solution for the sample reception area and preanalytics

OFFICIAL DEALER FOR T&O PRODUCTS

OPTIMIZE YOUR SAMPLE RECEPTION AREA AND WORKFLOWS

With the help of FLASH you can make your laboratory processes more efficient and increase your process reliability in preanalytics.

RELIABLE

The precise and reliable handling of sample tubes of the FLASH generates a high throughput. A plausibility check through the detection of the tube type and the comparison with the corresponding material identification improves the process assurance. Incorrect samples are detected early and sorted out before they enter the analytical process. Due to the early time stamp at sample receipt the tubes can be traced back through the entire laboratory process.

EASY

After arrival in the laboratory, the sample tubes are simply loaded into the hopper of the FLASH. Afterwards, the tubes are separated, registered, and sorted into the appropriate bins or racks. The simple handling of the FLASH and the automated sample registration considerably reduces the workload of the staff.

FLEXIBLE

The modular design of the FLASH enables a flexible adaptation to the laboratory processes as required. Bulk and rack modules can be combined arbitrarily in one system. The sorting rules can be setup according to the individual workflow requirements of the laboratory. In addition to the registration of samples, the FLASH optimizes subsequent processes through intelligent presorting and offers a complete solution for hematology/EDTA samples.

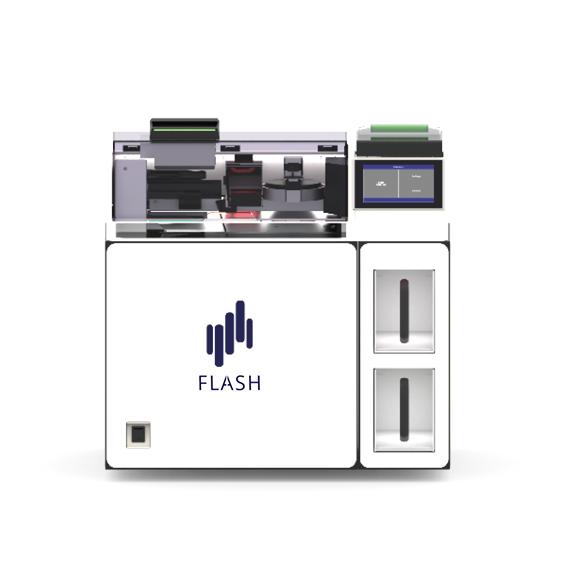

FLASH

BULK TO BULK

FLASH RS

BULK TO RACK

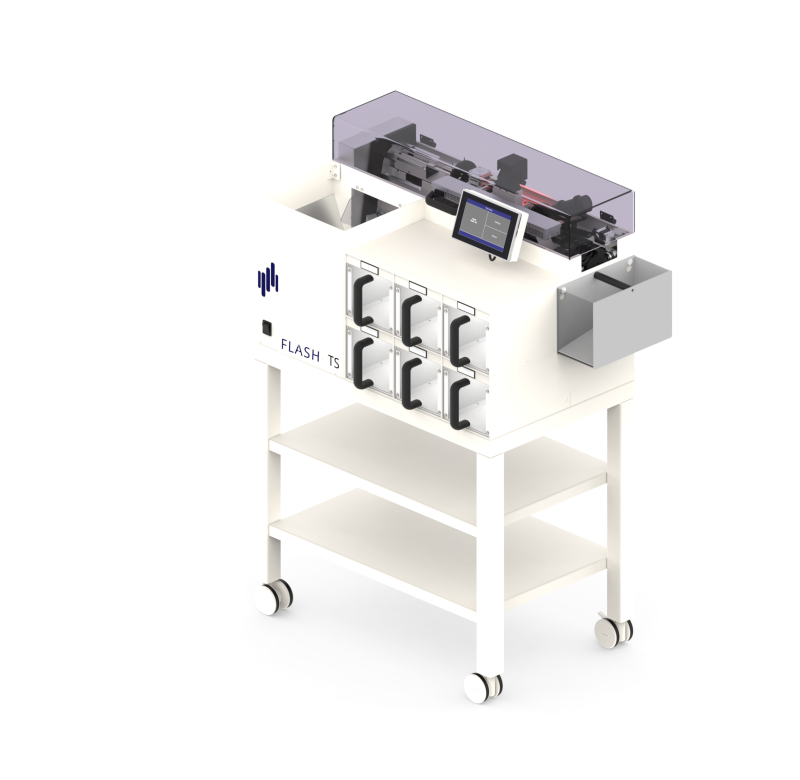

FLASH TS

COMPACT AND POWERFUL

EXPERIENCE THE EXTENSIVE MODULARITY

InTrac Intel

After unpacking, closed sample tubes are simply placed on InTrac and transported to the FLASH for registration and sorting.

- Simple handling

- Continuos feeding of FLASH for an early time stamp

- Continuous sample flow starting at the sample reception

- Reduction of walking distances

Base Unit

Manually or via an InTrac Inlet, samples can be loaded continuously into the spacious hopper of the FLASH. An integrated pane ensures a registration according to the FIFO concept.

- Capacity of up to 700 tubes

- Loading of STAT samples

- Registration of samples

- Identification of tube dimension via a high performance barcode scanner

- Highly reliable cap color identification with CapIdent due to in-house developed spectrometer

- Continuous loading of samples

- Status LED for a fast and easy visual check of the operational status

- Touchscreen with intuitive user interface for easy and simple operations

Bulk Output

After registration, samples are sorted into defined target bins as bulk. Sorting is based on costumer-defined rules using cap-color and/or barcode information or LIS-transmitted rules.

- Each bin has a capacity of up to 200 tubes

- Removal of bins at any time possible while FLASH keeps on running

- Number of tubes is counted for each bin

- Light barriers protect bins against over filling

- Wipers gently guide tubes into target bin

Rack & Bulk Output

Registered samples are sorted into costumer-defined racks or centrifuge buckets on a small footprint. In addition, this module comes with three target bins for sorting of tubes as bulk.

- High throughput of more than 1,300 tubes/hr for tubes sorted into racks

- Each module is equipped with a display for easy operation and status overview

- Easy access of all racks independent from their position in the rack area due to the new drawer

- Result record after final tube placement in rack

- Specific LOG for each RS2 Rack & Bulk Output module

- Barcode alignment of tubes within a rack (under development)

- Easy serviceability

SIQ Bin

Samples in question (SIQ) are sorted into the external SIQ bin. The samples can be picked up easily for further investigations. The SIQ bin is removed when using the InTrac Outlet connection. In this case, samples in question are routed to a defined bulk target bin instead.

InTrac Outlet

After registration, closed sample tubes are transported to the following work area in the laboratory or to another FLASH for further processing.

- Continuous sample flow to the next work area

- Reduction of walking distances

- Connectivity to other FLASH systems

- Barrier-free distribution of tubes throughout the whole laboratory

- Overcoming of height differences

Advantages

Improves workflow and performance.

Your employees are relieved of manual tasks.

Clear structure, intuitive operation and low maintenance requirements.

The use of almost wear-free components of the highest quality ensures the reliability and longevity of the devices.

Flash = Atras

Flash is the name of the product Atras in Spain and Portugal